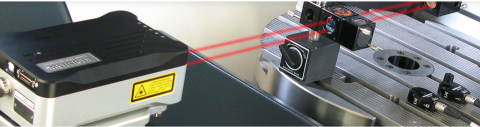

We feel proud to introduce ourselves as Machine Laser Calibration service providers to provide our customers best Laser Calibration Services with the help of Renishaw XL-80 and XC-80 laser instrument. The customers will have to provide the machine and we will guide you for any mechanical correction. We will pitch error compensation irrespective of the CNC system.

Portable QC20-W Wireless Ballbar

We are experts in CNC machine testing and correcting parameters with the help of Renishaw Ballbar Instrument. We have advanced instrument QC20 to check the inaccuracies of CNC machine. We have expertise in finding the errors and faulty area contributing your machine inaccuracy.

Complete kit with all its accessories:

- Extension up to Ø 1200 mm

- Lathe Kit

- Small circle (Ø 50 mm) kit

- VTL Adaptor

We are accomplished in rendering Laser Calibration service with Renishaw Instrument.The techniques of delivery used while rendering these have earned us enormous gratitude in this market. Appreciated broadly owing to their reliability, exactness, perfection and timeliness, these are broadly recommended.We perform CNC programming to suit our Laser software. We pitch error compensation irrespective of the CNC system and guide you for any mechanical correction. We have below instruments to provide these services:

- Renishaw XL-80 & XC-80 instrument with all required accessories.

- Renishaw Ballbar instrument.

- Renishaw tilting mirror

We have established ourselves in CNC Machine Calibration Services with the help of Renishaw XL-80 and XC-80 laser instrument. We offer laser Calibration & Compensation Linear Positioning Accuracy, Backlash and will help you to improve the accuracy of your CNC machines. Our customers will get a report containing measurement data. All data plot, and analysis of result as per VDI / ISO/ JIS Standards which will help in grading your machine. With this information, customers can maintain service logs demonstrating the accuracy of their machines. Our services also include consulting with many of you to customize a preventative maintenance program to minimize machine downtime and to ensure high quality products.

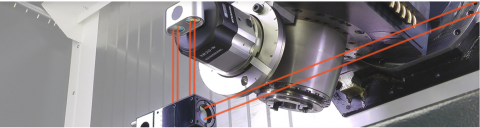

We are skilled in rendering Rotary Axis Calibration Service. Our professionals render our offered service using the advanced machines and techniques. Offered services are rendered in varied forms and terms that meet on consumer’s demand.

'Off axis' Rotary measurement:

Off axis rotary software allows the XR20-W to be used to measure the rotary positioning

the accuracy of an axis, even when the XR20-W isn't mounted on the center of rotation (pivot point) of that axis. This extends the capability of XR20-W to many five axis machine tools for evaluating rotating tool center point (RTCP).

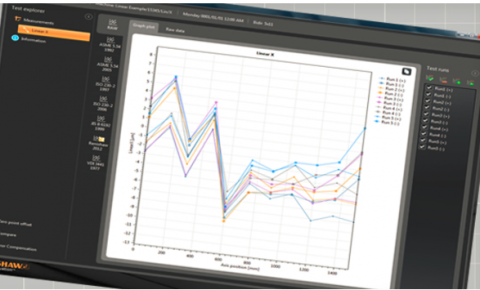

We offer our customers reports to analyze machine performance comprehensively and monitor trends over time. We help them to diagnose any problems quickly and plan in machine maintenance.

‘X Cal-View’ new data analysis software:

Analysis & data plot result as per latest available International Standards VDI / ISO / JIS which could grade machine, plan proactive maintenance action and maintain the machine history.